While Industry 4.0 is all about “Data Automation” and making Data available and retrievable easily, anywhere, anytime according to authorization …apart from convenience and working remotely what Qualitative advantage would it offer?.

Anything that is capable of making a significant difference to Business must have already been monitored and acted upon with or without Automation so what tangible difference would I4.0 make?

What are being sold as “Key Industry 4.0 features” in Machine Tools are OEE, Predictive Maintenance and Energy Consumption Monitoring ….now the question to be asked is:

“Did Industry not monitor these attributes prior to I4.0 … if and when it was considered important enough?”

The whole benefit then boils down to conceding that “Since Industry 4.0 makes it much easier to do it now, therefore if it could be pursued profitably now”

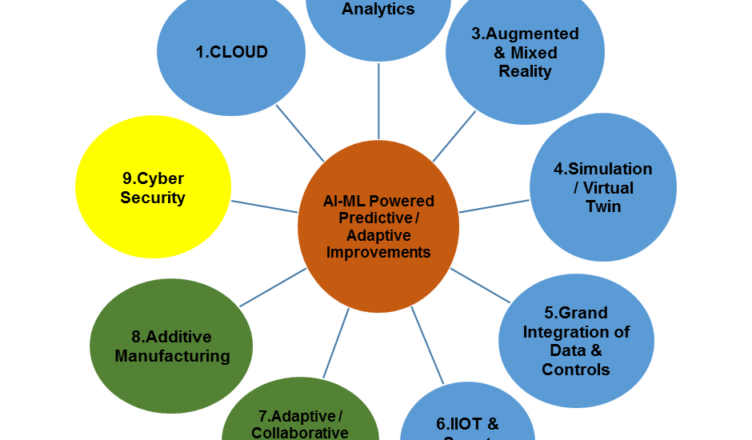

In the famous 9 element chart depicting Industry 4.0; if AI-ML does not sit in the middle and through “Data Mining” and “Deep Learning” arrive at some “Intelligence” that was heretofore not possible …and that “Intelligence” changes the game and the way Business / Industry would work, so disruptively that it becomes a survival issue to pursue the same …implementing Industry 4.0 would not make commercial sense otherwise.

Comparisons are not difficult to see … for example “there is was really NO relation between having Cell Phone and having Credit / Debit card and net banking not so long back ….but technology has changed the way identity is ascertained even for financial transactions, and so today it has become impossible to survive without Smart Phone and e-Commerce”

If Industry 4.0 is about total automation Industry 5.0 is all about having “human” touch, creativity and ingenuity into every premium Product / Service. This means our machines and manufacturing system would have to adapt to human vagaries and variabilities for collaborative working. If a Robot has to work with human operative … the operative would not like to press a button or type a cryptic command for Robot …it is expected that Robot learns operatives commands through speech and body language.

It means going further, machines have to have speech recognition, gesture recognition, biometric identification capability and handwritten text recognition. All these would make machines heavily based on AI-ML.

AVINASH KHARE

Advisor – IMTMA Technology Centre, PUNE