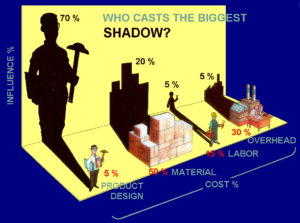

Design, Production, Inspection, supply chain etc. are the various functions of product Ecosystem. Design is the very important function of this Ecosystem. Design decides, how part/product should be and other functions just follow them. Hence responsibility on design for product performance and success is very high. Literature says, design determines more than 70% of the product total cost (see figure). Hence it is very important to have robust design with low cost. If the design to be clear and robust, design intent to be communicated without any ambiguity.

Literature also says, flawless communications bring down errors or failures drastically during manufacturing. Hence it is very important to have explicit communication between design and manufacturing. GD&T is the powerful tool that helps to communicate design intent crystal clear, there by reducing cost of manufacturing.

Many features of GD&T focused on cost reduction without compromising the functionality. It is a myth in an industry today, GD&T callouts increase the cost of manufacturing. Here are few features of GD&T that focused on cost reduction.

- If you use GD&T Cylindrical tolerance you will get 57% more tolerance

- If you use MMC or LMC modifiers as per GD&T standard, you will get BONUS tolerance

- Use of DATUM system, eliminate/Reduce defective parts

- Datum Shift provide you easy assembly without compromising product performance

- Composite tolerances provide you wider tolerance to pattern locating dimensions as per the functional requirement.

Many more like this in GD&T that leads to low cost manufacturing. This is possible only when, you learn how to read and interpret GD&T. It is important for design, production and Inspection engineers to learn how to interpret GD&T as per standard and successfully design and manufacture Low cost high performance products.

Ganapathi. K N

Advisor, IMTMA